Reinforcement around openings like windows and doors etc

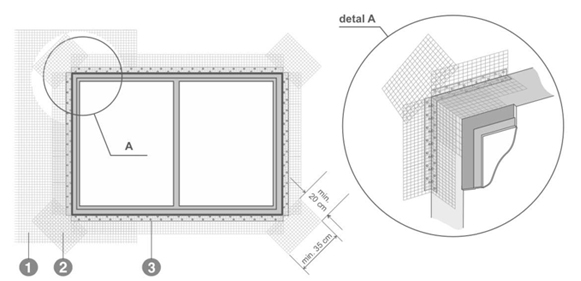

Fig. 7. The method of sticking the fiberglass mesh at the window and door openings.

1 – fiberglass mesh (cut the mesh strip to the edge of the corner)

2 – pieces of mesh reinforcing the corners of the opening

3 – protective corner with fiberglass mesh

Before starting the execution of the reinforced layer on the walls:

– embed the protective corners with the mesh on the corners of the building walls, on the

corners of the entrance doors and windows,

– reinforce all corners of the openings by sticking them to the mesh, at least 20x35cm –

sticking them at an angle of about 45o.

– make the necessary expansion joints using sealing tapes or expansion profiles *.

* Rules for making expansion joints on perlittifacades

Expansion joints are usually performed:

• in internal corners of buildings,

• in the event of changes in the foundation heights,

• in long or high walls

• in places of faults (or changes in height) on facades,

• in places of expansion joints of building structures.

The method of execution and the place of the expansion joint should be indicated by the designer of the insulation in the design documentation building facade. The joints of the insulation boards with the joinery, window sills and sheet metal work should be permanently sealed with materials

flexible, e.g. silicone putties or impregnated foamed plastics tapes. Convenient solution is the use of special window strips, which are also perfect for these places. The need for careful sealing of these places is due to the fact that the flashing and the carpentry (ironwork) under due to heat, they expand differently than plaster. In these places, scratches form, through

which over time rainfall, water seeps in, moistening the walls and reducing the durability of the insulation. In the autumn and winter periods the process of lowering the durability additionally accelerates and intensifies the frost.

The execution of the reinforced layer should start with the wall corners, openings and expansion joints. Adhesive mortar SPECIAL is applied to the surface of mineral wool boards with a continuous layer of approx. 3 mm thickness. To apply the mortar, a notched trowel with a tooth size of 10-12mm is used. The mortar is applied in vertical stripes with the width of a fiberglass mesh. After applying the adhesive mortar, immediately sink (press) into several mesh in the mortar at the top of the wall, stretch (tighten) the bottom part of the mesh and press it onto the top of the wall the entire width, avoiding the formation of waves, humps and bulges. The net must be fully pressed in into the mortar. It is unacceptable for the net to be placed directly on the wool surface and not to be visible in the face of the reinforcement. The thickness of the mortar layer when using a single layer of mesh should be no less than 3 mm and not more than 5 mm.